Pipe Notching Template

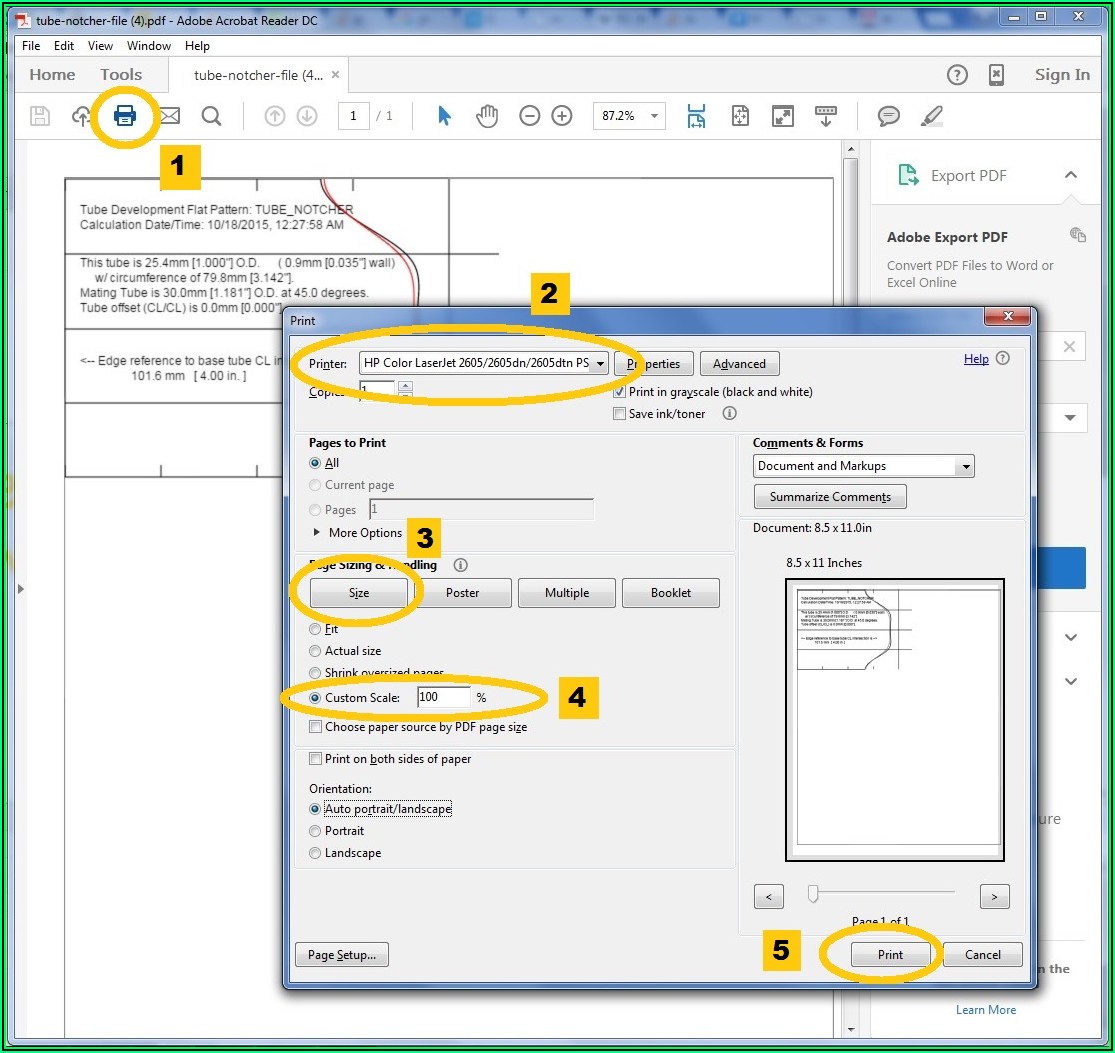

Pipe Notching Template - Pipe tube notching join profile diagram. Web the perfect tool for:automotive, marine,and industrial welding. Web homemade a template for cutting pipe.tube notching. Web tubemiter plots out a curved line that can be wrapped around a tube and used as a template for cutting. That's the easiest way to do it is you have the right bit and a good drill press, or a milling machine. Pipe end view diagram with wall thickness. Print tube coping template at 100% printer scale, cut and wrap around cut tube to trace with marker pen. In this video easy way to notching pipe. Web pipe notching full scale printable template download pdf for larger templates, only half is drawn so it will fit on a page easier. Layout complicated tube joints in seconds!

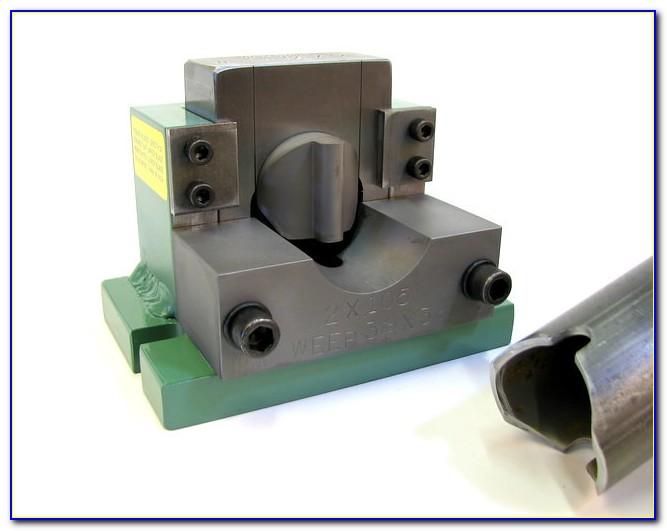

3.14 common sizes a few notes if you try to enter a tube size that's over 10 inches in diameter (or under.1), you'll end up back at 1 inch. Print tube coping template at 100% printer scale, cut and wrap around cut tube to trace with marker pen. In this video easy way to notching pipe. It is a simple (and free) shareware program that has been around a long time and runs as a. Pipe tube notching join profile diagram. That's the easiest way to do it is you have the right bit and a good drill press, or a milling machine. Web take a circle drill the size of the diameter of the pipe you are attaching to, always a perfect notch, no shitting around with a grinder. Just press, transfer, and trace! For a snug fit at the outside of the tube, enter 0 cut tube wall thick and grind inside of tube to fit. As you know pipe notching tools like hole saw.

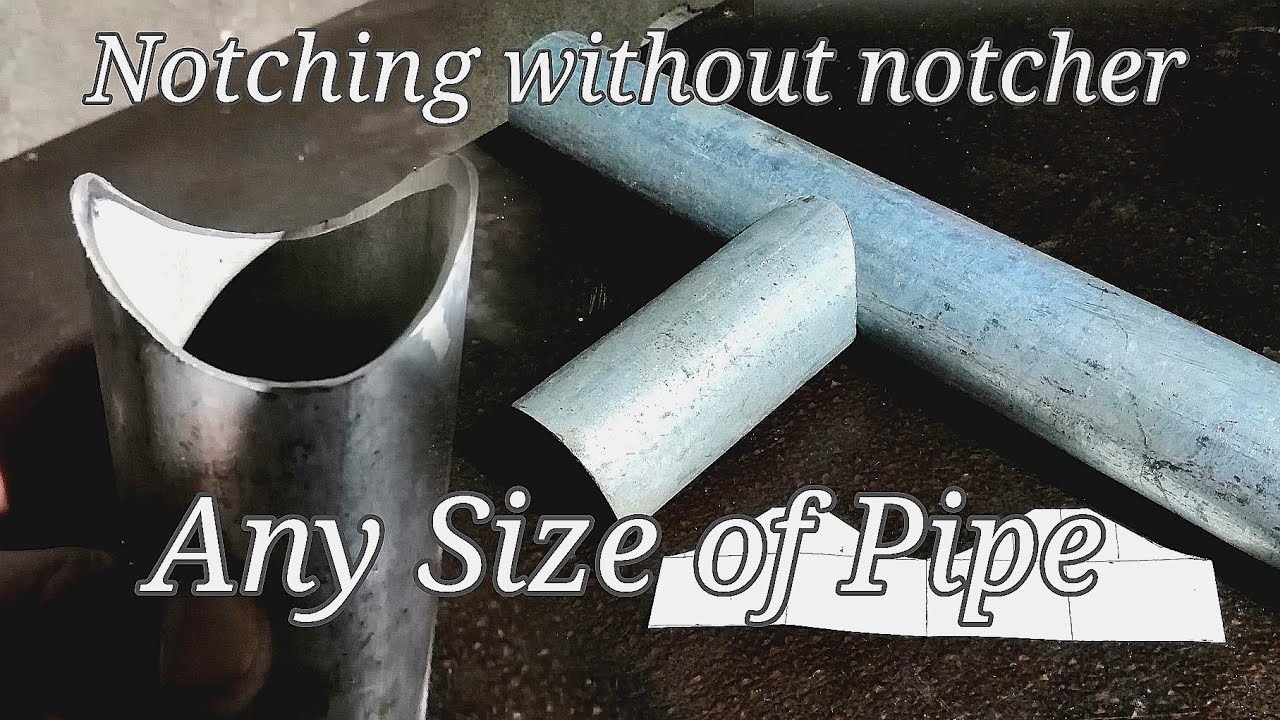

Web tubemiter plots out a curved line that can be wrapped around a tube and used as a template for cutting. That's the easiest way to do it is you have the right bit and a good drill press, or a milling machine. The perfect tube coping or pipe notching tool. This technique works best for 90 degree pipe joint. In this video easy way to notching pipe. Pipe end view diagram with wall thickness download pdf angle Pipe tube notching full scale printable template. Pipe tube notching join profile diagram. It is a simple (and free) shareware program that has been around a long time and runs as a. Pdf png postscript hpgl g code pattern height:

Automedia 2000

Web homemade a template for cutting pipe.tube notching. Web the perfect tool for:automotive, marine,and industrial welding. The perfect tube coping or pipe notching tool. As you know pipe notching tools like hole saw. Print 2 templates, reverse 1 and tape to the other to create a full template, or print 1 template, mark 1 side then reverse to mark the.

Complete plans for DIY Abrasive Tube Notcher Kustoms by Kent Diy

Web for a snug fit at the outside of the tube, enter 0 cut tube wall thick and grind inside of tube to fit. Making excellent tool from a plastic bottle! Web take a circle drill the size of the diameter of the pipe you are attaching to, always a perfect notch, no shitting around with a grinder. Pipe tube.

pipe saddles

If cut tube wall thick is larger than 0, the cut fits to the inside diameter of the tube, making a notch for welding. Pipe end view diagram with wall thickness. In this video easy way to notching pipe. A good fit means good welds, so you can save time and eliminate wasted material! Print 2 templates, reverse 1 and.

Homemade Template for Cutting Pipe. The Perfect Tube Coping or Pipe

Making excellent tool from a plastic bottle! Pipe end view diagram with wall thickness. Web pipe notching full scale printable template download pdf for larger templates, only half is drawn so it will fit on a page easier. Pipe tube notching full scale printable template. Web homemade a template for cutting pipe.tube notching.

Printable Tube Notching Templates Template 1 Resume Examples

For a snug fit at the outside of the tube, enter 0 cut tube wall thick and grind inside of tube to fit. In this video easy way to notching pipe. The perfect tube coping or pipe notching tool. Pdf png postscript hpgl g code pattern height: A good fit means good welds, so you can save time and eliminate.

The manaul method for designing a pipe to pipe branch ?!! Pipelines

A good fit means good welds, so you can save time and eliminate wasted material! Pipe end view diagram with wall thickness. The reason for this is that the overall calculation gets too big to handle here, and php runs out of memory. 3.14 common sizes a few notes if you try to enter a tube size that's over 10.

Pipe Notching Template Master of Documents

This technique works best for 90 degree pipe joint. Pdf png postscript hpgl g code pattern height: Pipe tube notching full scale printable template. Web the perfect tool for:automotive, marine,and industrial welding. 3.14 common sizes a few notes if you try to enter a tube size that's over 10 inches in diameter (or under.1), you'll end up back at 1.

The Best Idea How to make Template for Notching any Equal size of pipe

A good fit means good welds, so you can save time and eliminate wasted material! Pipe tube notching join profile diagram. Web the perfect tool for:automotive, marine,and industrial welding. 3.14 common sizes a few notes if you try to enter a tube size that's over 10 inches in diameter (or under.1), you'll end up back at 1 inch. In this.

Tube notching tool kit. Every welder needs this tool! The perfect tube

This technique works best for 90 degree pipe joint. It is a simple (and free) shareware program that has been around a long time and runs as a. Layout complicated tube joints in seconds! Web tubemiter plots out a curved line that can be wrapped around a tube and used as a template for cutting. Making excellent tool from a.

London Tube Map Art Print Maps Resume Examples q25Ze1jD0o

As you know pipe notching tools like hole saw. Web for a snug fit at the outside of the tube, enter 0 cut tube wall thick and grind inside of tube to fit. That's the easiest way to do it is you have the right bit and a good drill press, or a milling machine. The perfect tube coping or.

A Good Fit Means Good Welds, So You Can Save Time And Eliminate Wasted Material!

It is a simple (and free) shareware program that has been around a long time and runs as a. Pipe tube notching join profile diagram. Pipe notching full scale printable template. For a snug fit at the outside of the tube, enter 0 cut tube wall thick and grind inside of tube to fit.

Print Tube Coping Template At 100% Printer Scale, Cut And Wrap Around Cut Tube To Trace With Marker Pen.

3.14 common sizes a few notes if you try to enter a tube size that's over 10 inches in diameter (or under.1), you'll end up back at 1 inch. As you know pipe notching tools like hole saw. The perfect tube coping or pipe notching tool. Pipe tube notching full scale printable template.

Web Take A Circle Drill The Size Of The Diameter Of The Pipe You Are Attaching To, Always A Perfect Notch, No Shitting Around With A Grinder.

In this video easy way to notching pipe. Just press, transfer, and trace! Web homemade a template for cutting pipe.tube notching. Web pipe notching full scale printable template download pdf for larger templates, only half is drawn so it will fit on a page easier.

Print 2 Templates, Reverse 1 And Tape To The Other To Create A Full Template, Or Print 1 Template, Mark 1 Side Then Reverse To Mark The Other.

That's the easiest way to do it is you have the right bit and a good drill press, or a milling machine. This technique works best for 90 degree pipe joint. Web for a snug fit at the outside of the tube, enter 0 cut tube wall thick and grind inside of tube to fit. The reason for this is that the overall calculation gets too big to handle here, and php runs out of memory.