Lewis Form Factor

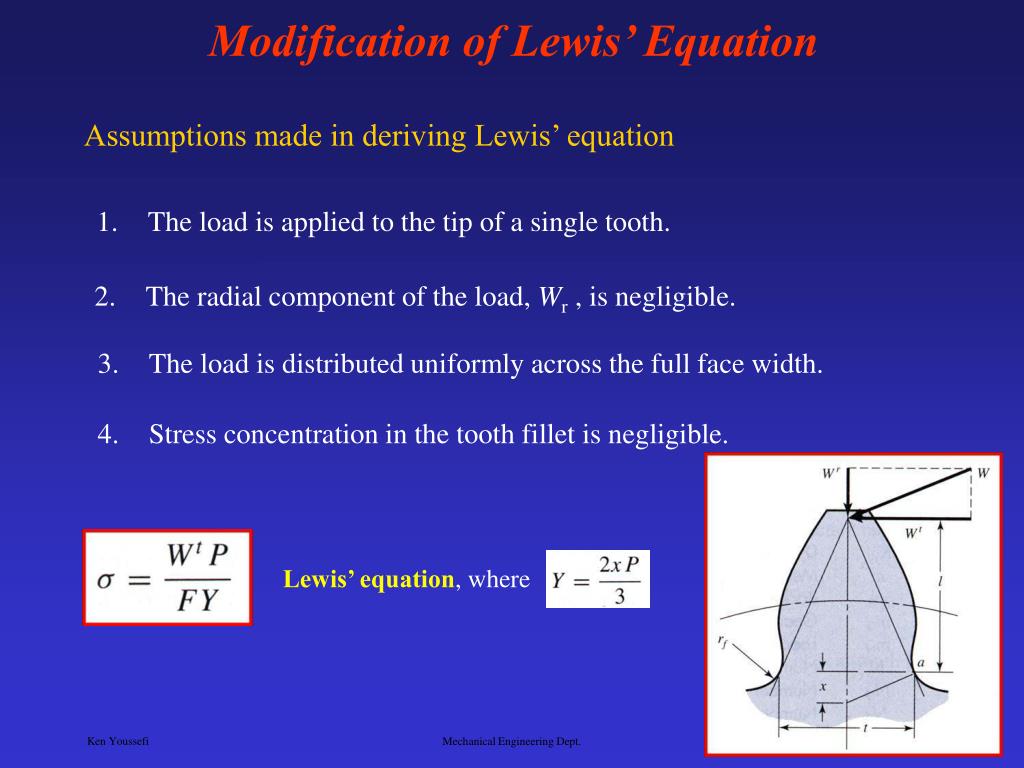

Lewis Form Factor - 6 + 4(7) = 34. This factor takes in all the geometric variances with the involute profile and puts them in a neat little table. Web tangent, the lewis equation for the tooth bending stress is expressed as: Y = 0.154 − 0.912 t where t = number of teeth. Web the determination of the lewis form factor and the agma geometry factor j for external spur gear teeth The molar mass of if3 is 183.9 g/mol. Lewis formulas are structures that show the connectivity, or bonding sequence of the atoms, indicating single, double, or triple bonds. Consider the lewis structure for sulfur tetrafluoride (sf 4) which contains 34 valence electrons. Web this research aims at revising the lewis model by making adjustments for dynamic loads, shear stresses, axial bending stress for helical gears, and stress concentration factor. Web i've been looking for a practical way to determine the lewis form factors y for gears.

Web i've been looking for a practical way to determine the lewis form factors y for gears. It is a function of the number of teeth, pressure angle, and involute depth of the gear and is. Web characteristics of lewis formulas: Web the lewis form factor is a function of the number of teeth n and the pressure angle φ and is given in the following chart. The calculation of bending stress in gear teeth can be based on the lewis formula. The y = 1.5 value is used in the calculation. This factor takes in all the geometric variances with the involute profile and puts them in a neat little table. The molar mass of if3 is 183.9 g/mol. 10k views 2 years ago mechanical engineering design i. Find more chemistry widgets in wolfram|alpha.

Pressure angle [deg] s v. The lewis form factor is an empirical correction factor that approximates the. Note that the old 14.5 degree form. 10k views 2 years ago mechanical engineering design i. Web cite permissions this paper presents a simple and direct approach to the problem of the definition of the root profile for standard and nonstandard external spur gear teeth. Consider the lewis structure for sulfur tetrafluoride (sf 4) which contains 34 valence electrons. Web get the free lewis structure widget for your website, blog, wordpress, blogger, or igoogle. Y = 0.154 − 0.912 t where t = number of teeth. This factor is defined as y= (t^2 x dp)/6l, where t= tooth thickness at critical. Web tangent, the lewis equation for the tooth bending stress is expressed as:

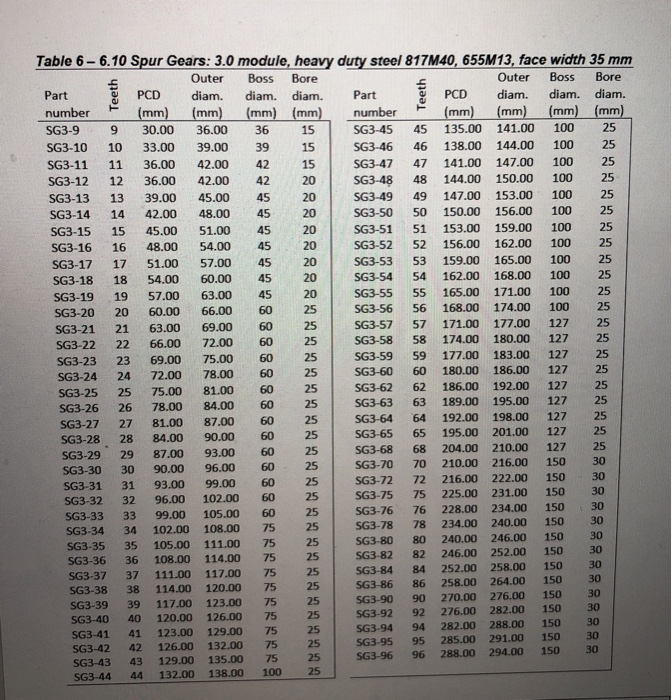

Solved 13. A double reduction gearbox is required to

6 + 4(7) = 34. Lewis form factor, velocity factor, kv, lewis bending stress, show more. Web cite permissions this paper presents a simple and direct approach to the problem of the definition of the root profile for standard and nonstandard external spur gear teeth. Lewis form factor for 20° full depth involute system is given by: Web characteristics of.

Lewis Factor Equation for Gear Tooth Calculations

Where w t = transmitted load (n), f = face width (m or mm), m = module. Web characteristics of lewis formulas: Web cite permissions this paper presents a simple and direct approach to the problem of the definition of the root profile for standard and nonstandard external spur gear teeth. Web the determination of the lewis form factor and.

Engineer Haven Formula Sheet

This factor is defined as y= (t^2 x dp)/6l, where t= tooth thickness at critical. Web this gear strength calculator uses the lewis form factor to calculate the strength of a gear. This factor takes in all the geometric variances with the involute profile and puts them in a neat little table. Web tangent, the lewis equation for the tooth.

Gear stress lewis_formula

Web the determination of the lewis form factor and the agma geometry factor j for external spur gear teeth Web characteristics of lewis formulas: Web this research aims at revising the lewis model by making adjustments for dynamic loads, shear stresses, axial bending stress for helical gears, and stress concentration factor. Relief of crown at the ends of the teeth..

Designing With Plastic Gears and General Considerations of Plastic Gearing

Web cite permissions this paper presents a simple and direct approach to the problem of the definition of the root profile for standard and nonstandard external spur gear teeth. Web i've been looking for a practical way to determine the lewis form factors y for gears. Web this research aims at revising the lewis model by making adjustments for dynamic.

STEM Gear Tooth Strength and the Lewis Form Factor YouTube

The maximum stress probably occurs. Lewis bending stress at the teeth of a gear in just over 1. Hence the lewis form factor (y) is only. Web lewis form factorvelocity factor, kvlewis bending stressbending stress at the teethprevious video: It is a function of the number of teeth, pressure angle, and involute depth of the gear and is.

Engineer Haven Formula Sheet

Lewis formulas are structures that show the connectivity, or bonding sequence of the atoms, indicating single, double, or triple bonds. 10k views 2 years ago mechanical engineering design i. The y = 1.5 value is used in the calculation. Web cite permissions this paper presents a simple and direct approach to the problem of the definition of the root profile.

PPT Force Analysis Spur Gears PowerPoint Presentation, free

The calculation of bending stress in gear teeth can be based on the lewis formula. Web lewis form factorvelocity factor, kvlewis bending stressbending stress at the teethprevious video: 10k views 2 years ago mechanical engineering design i. This factor takes in all the geometric variances with the involute profile and puts them in a neat little table. The maximum stress.

2014W ENGR380 Lecture18 Spur Gear Design (Lewis Equation for Tooth

Hence the lewis form factor (y) is only. There are four covalent bonds in the skeleton. Lewis bending stress at the teeth of a gear in just over 1. The molar mass of if3 is 183.9 g/mol. Lewis form factor, velocity factor, kv, lewis bending stress, show more.

Lewis Factor Equation for Gear Tooth Calculations

Hence the lewis form factor (y) is only. This factor takes in all the geometric variances with the involute profile and puts them in a neat little table. Web lewis form factor obtained from a tooth layout. Web the lewis form factor is the real genius of the operation. Consider the lewis structure for sulfur tetrafluoride (sf 4) which contains.

10K Views 2 Years Ago Mechanical Engineering Design I.

Lewis form factor, velocity factor, kv, lewis bending stress, show more. There are four covalent bonds in the skeleton. Pressure angle [deg] s v. Consider the lewis structure for sulfur tetrafluoride (sf 4) which contains 34 valence electrons.

Web Lewis Form Factorvelocity Factor, Kvlewis Bending Stressbending Stress At The Teethprevious Video:

Web tangent, the lewis equation for the tooth bending stress is expressed as: Y = 0.154 − 0.912 t where t = number of teeth. Web characteristics of lewis formulas: It is a function of the number of teeth, pressure angle, and involute depth of the gear and is.

Where W T = Transmitted Load (N), F = Face Width (M Or Mm), M = Module.

The molar mass of if3 is 183.9 g/mol. 6 + 4(7) = 34. Lewis formulas are structures that show the connectivity, or bonding sequence of the atoms, indicating single, double, or triple bonds. The lewis form factor is an empirical correction factor that approximates the.

This Factor Is Defined As Y= (T^2 X Dp)/6L, Where T= Tooth Thickness At Critical.

Web this research aims at revising the lewis model by making adjustments for dynamic loads, shear stresses, axial bending stress for helical gears, and stress concentration factor. Lewis bending stress at the teeth of a gear in just over 1. Web cite permissions this paper presents a simple and direct approach to the problem of the definition of the root profile for standard and nonstandard external spur gear teeth. Web the lewis form factor is the real genius of the operation.