Fall Protection Inspection Form

Fall Protection Inspection Form - Web fall protection inspection forms proper maintenance and inspection of your safety equipment is key to ensuring your workers remain safe on the job. Web inspecting your fall protection equipment is one of the most important, but often neglected, tasks before starting a job at height. ________________ daily fall protection inspection form operator: Web this fall protection plan is specific to the following project, in accordance with company policies and procedures as outlined in the fall protection plan: Pass, safe for use red: Description location of job date plan prepared or modified plan prepared by (designated competent person) plan approved by plan supervised by (designated qualified person) details Web daily fall protection inspection form job name: __________________________________ daily fall protection inspection form ___________________________________________ operator signature. Web your safety while working at height depends on effective inspection of your fall protection equipment before and after use. Download our free fall protection inspection forms today for a comprehensive inspection checklist on a variety of fall protection products.

Classification destroy immediately _____ company _____ fall protection equipment inspection log appendix 2: Web this fall protection plan is specific to the following project, in accordance with company policies and procedures as outlined in the fall protection plan: Visual and touch inspection cuts, nicks or tears broken fibers/cracks Fall protection equipment inspection created date: ________________ daily fall protection inspection form operator: Download our free fall protection inspection forms today for a comprehensive inspection checklist on a variety of fall protection products. This creates surface tension making damaged fibers or cuts easier to see. Web grasp the webbing with your hands and bend the webbing, checking both sides. Web osha requires that fall protection be provided at elevations of four feet in general industry workplaces, five feet in shipyards, six feet in the construction industry and eight feet in longshoring operations. Web daily fall protection inspection form job name:

Visual and touch inspection cuts, nicks or tears broken fibers/cracks ________________ daily fall protection inspection form operator: Download our free fall protection inspection forms today for a comprehensive inspection checklist on a variety of fall protection products. Description location of job date plan prepared or modified plan prepared by (designated competent person) plan approved by plan supervised by (designated qualified person) details Web osha requires that fall protection be provided at elevations of four feet in general industry workplaces, five feet in shipyards, six feet in the construction industry and eight feet in longshoring operations. This creates surface tension making damaged fibers or cuts easier to see. Pass, safe for use red: Fall protection equipment inspection created date: Web daily fall protection inspection form job name: These forms are for use by a fall protection equipment inspector having the training qualifications, expertise and ability to detect faults in height safety equipment.

11 Best Images of JSA Worksheet Template Job Demands Analysis

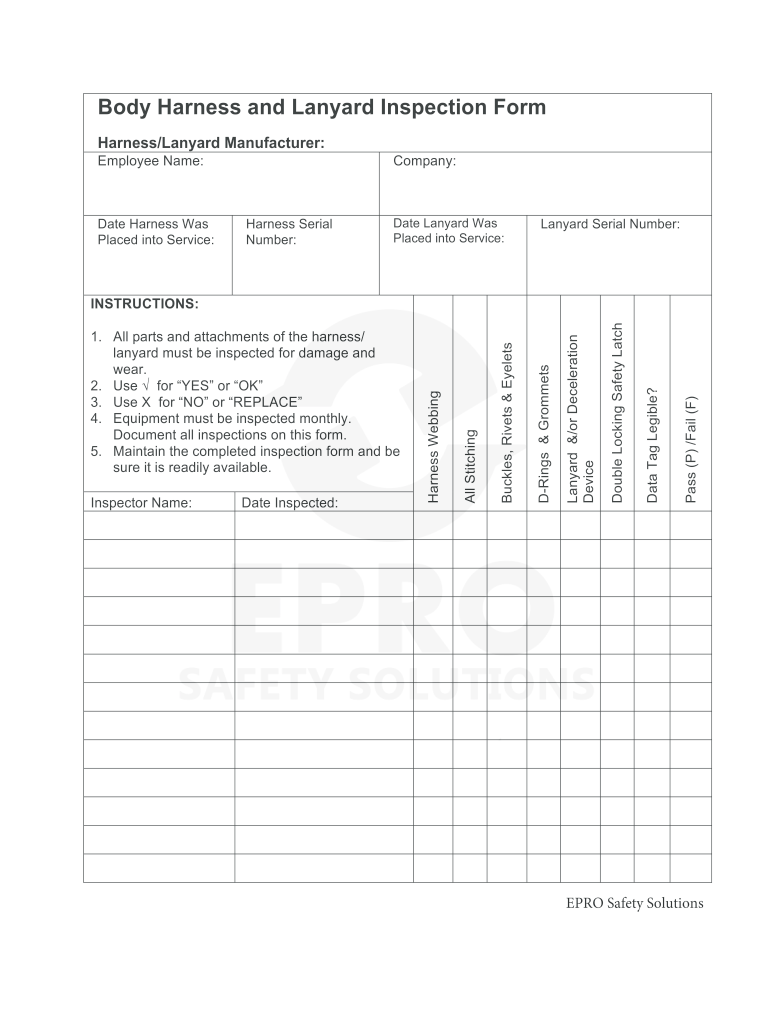

Full body harness osha 1926.502(d)(21) personal fall arrest systems shall be inspected prior to each use for wear, damage, and other deterioration, and defective components shall be removed from service. These forms are for use by a fall protection equipment inspector having the training qualifications, expertise and ability to detect faults in height safety equipment. Fall protection equipment inspection created.

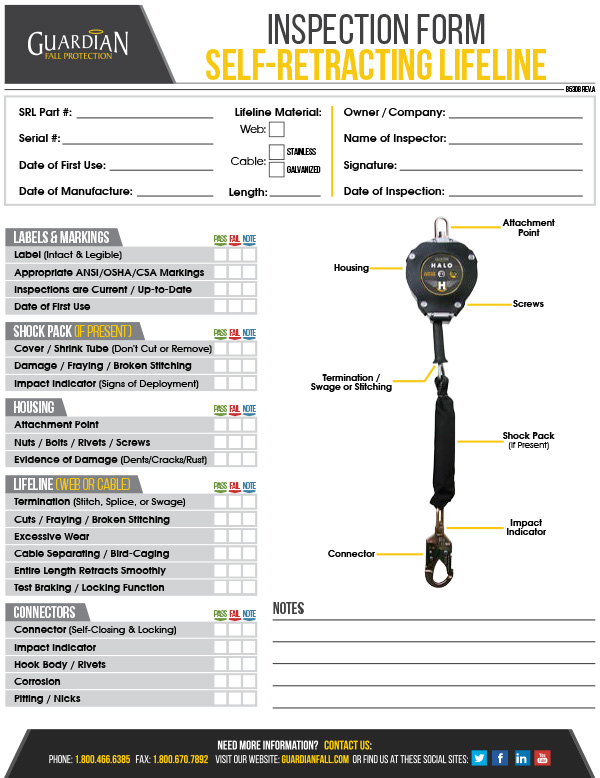

Statement from Guardian Fall Protection Blog Columbia Safety and Supply

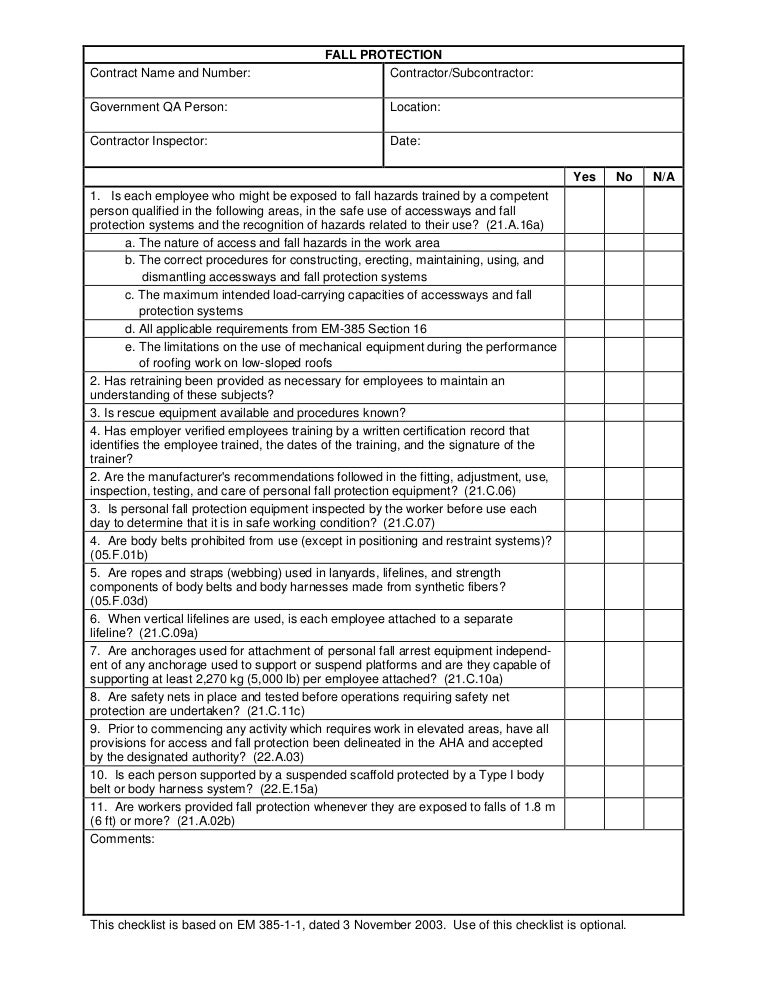

Web osha requires that fall protection be provided at elevations of four feet in general industry workplaces, five feet in shipyards, six feet in the construction industry and eight feet in longshoring operations. Web grasp the webbing with your hands and bend the webbing, checking both sides. This creates surface tension making damaged fibers or cuts easier to see. Classification.

Pin on Template DOCs

Pass, safe for use red: Web this fall protection plan is specific to the following project, in accordance with company policies and procedures as outlined in the fall protection plan: __________________________________ daily fall protection inspection form ___________________________________________ operator signature. ________________ daily fall protection inspection form operator: Web your safety while working at height depends on effective inspection of your fall.

301 Moved Permanently

Web fall protection inspection forms proper maintenance and inspection of your safety equipment is key to ensuring your workers remain safe on the job. Web grasp the webbing with your hands and bend the webbing, checking both sides. Pass, safe for use red: This creates surface tension making damaged fibers or cuts easier to see. Fall protection equipment inspection created.

Safety Harness Inspection Checklist Inspection checklist, Checklist

These forms are for use by a fall protection equipment inspector having the training qualifications, expertise and ability to detect faults in height safety equipment. Fall protection equipment inspection created date: Web grasp the webbing with your hands and bend the webbing, checking both sides. Full body harness osha 1926.502(d)(21) personal fall arrest systems shall be inspected prior to each.

Harness Inspection Template Hvac inspection report template and house

Full body harness osha 1926.502(d)(21) personal fall arrest systems shall be inspected prior to each use for wear, damage, and other deterioration, and defective components shall be removed from service. Web fall protection inspection forms proper maintenance and inspection of your safety equipment is key to ensuring your workers remain safe on the job. Web osha requires that fall protection.

Harness Inspection Template Equipment Inspection Forms Chainimage

________________ daily fall protection inspection form operator: Web your safety while working at height depends on effective inspection of your fall protection equipment before and after use. Full body harness osha 1926.502(d)(21) personal fall arrest systems shall be inspected prior to each use for wear, damage, and other deterioration, and defective components shall be removed from service. Web daily fall.

Public Services Health and Safety Association Personal Fall

These forms are for use by a fall protection equipment inspector having the training qualifications, expertise and ability to detect faults in height safety equipment. Web daily fall protection inspection form job name: This creates surface tension making damaged fibers or cuts easier to see. Web your safety while working at height depends on effective inspection of your fall protection.

Fall Protection Self Inspection Checklist Manufactured Goods Transport

Web this fall protection plan is specific to the following project, in accordance with company policies and procedures as outlined in the fall protection plan: Description location of job date plan prepared or modified plan prepared by (designated competent person) plan approved by plan supervised by (designated qualified person) details Visual and touch inspection cuts, nicks or tears broken fibers/cracks.

Fall protection checklist usace

Classification destroy immediately _____ company _____ fall protection equipment inspection log appendix 2: __________________________________ daily fall protection inspection form ___________________________________________ operator signature. Download our free fall protection inspection forms today for a comprehensive inspection checklist on a variety of fall protection products. This creates surface tension making damaged fibers or cuts easier to see. Description location of job date plan.

Fall Protection Equipment Inspection Created Date:

Web grasp the webbing with your hands and bend the webbing, checking both sides. Classification destroy immediately _____ company _____ fall protection equipment inspection log appendix 2: This creates surface tension making damaged fibers or cuts easier to see. Full body harness osha 1926.502(d)(21) personal fall arrest systems shall be inspected prior to each use for wear, damage, and other deterioration, and defective components shall be removed from service.

Web This Fall Protection Plan Is Specific To The Following Project, In Accordance With Company Policies And Procedures As Outlined In The Fall Protection Plan:

Download our free fall protection inspection forms today for a comprehensive inspection checklist on a variety of fall protection products. __________________________________ daily fall protection inspection form ___________________________________________ operator signature. Visual and touch inspection cuts, nicks or tears broken fibers/cracks Web inspecting your fall protection equipment is one of the most important, but often neglected, tasks before starting a job at height.

Web Fall Protection Inspection Forms Proper Maintenance And Inspection Of Your Safety Equipment Is Key To Ensuring Your Workers Remain Safe On The Job.

We’ve created these handy checklists to make inspecting the condition of your malta dynamics equipment a seamless part of your everyday process. Web daily fall protection inspection form job name: Web your safety while working at height depends on effective inspection of your fall protection equipment before and after use. Pass, safe for use red:

Description Location Of Job Date Plan Prepared Or Modified Plan Prepared By (Designated Competent Person) Plan Approved By Plan Supervised By (Designated Qualified Person) Details

________________ daily fall protection inspection form operator: These forms are for use by a fall protection equipment inspector having the training qualifications, expertise and ability to detect faults in height safety equipment. Web osha requires that fall protection be provided at elevations of four feet in general industry workplaces, five feet in shipyards, six feet in the construction industry and eight feet in longshoring operations.