Construction Form Work

Construction Form Work - When the idea of a form is this versatile, it is crucial that your conception of a construction form is flexible, requiring minimal change when needed. Materials 1×4 wood boards for building the formworks 2×4 wood stakes to lock into position the formwork for concrete 2×4 lumber for securing the forms nails/wood screws to fasten the formwork polystyrene sheets to insulate the foundation (optional) tools safety gloves, glasses In specialty applications formwork may be permanently incorporated into the final structure, adding insulation or helping reinforce the finished structure. Web #1 inspection forms construction companies are required to perform routine inspections for many different purposes. The problem with building construction is the lack of support for the weight of the materials. Web construction loan agreement form. We also provide forming and shoring products including: We will have the right forms to fit your design and a knowledgeable staff to assist with your project. Formwork can be of timber, steel, plastic, or fiberglass. If you dream it, we can form it.

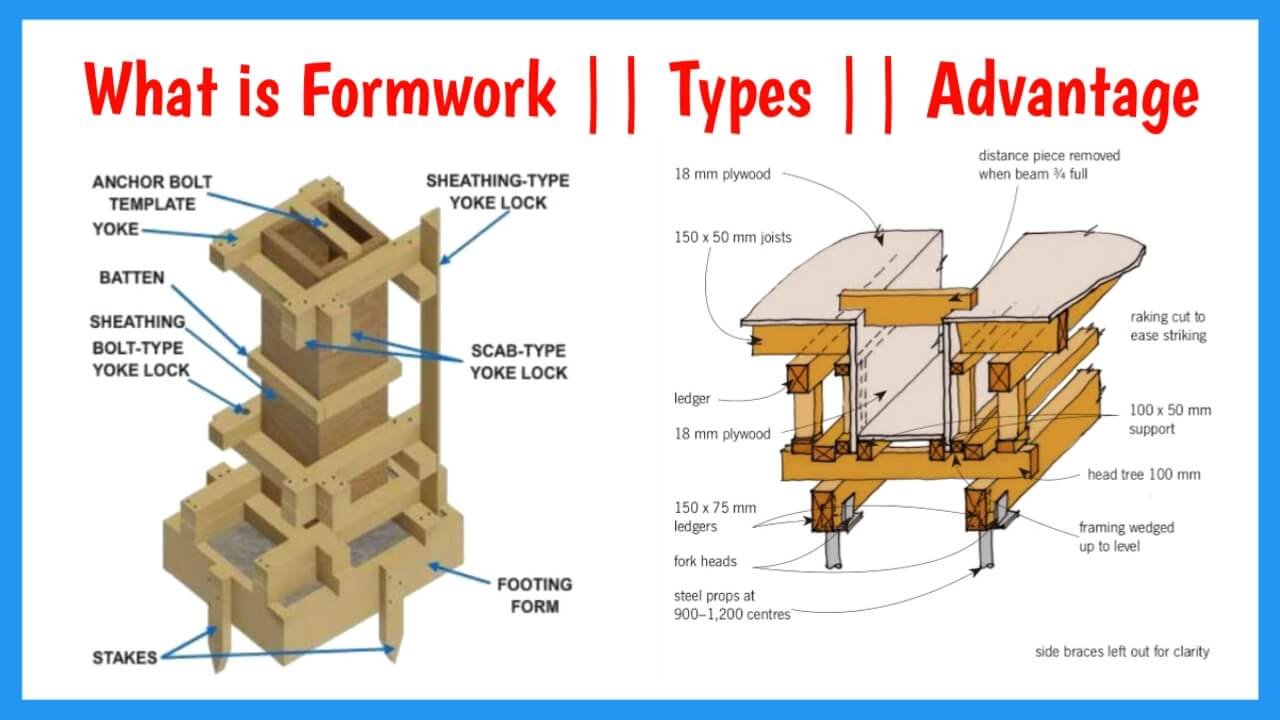

We also provide forming and shoring products including: The problem with building construction is the lack of support for the weight of the materials. Formwork cost is 25 to 30% of the total cost. Web precise aluminum forms are perfect for concrete multistory housing complexes such as apartments and condominiums. Web construction loan agreement form. Wall, slab, climbing, shoring, safety and components. Types of concrete formwork construction depends on formwork material and type of structural element. Web in order to build formwork for foundation, you need the following: To effectively develop a jobsite plan involves communication between all parties, including the concrete contractor and the formwork supplier. Web formwork is the mould which is used in construction for giving desire structural shape by pouring concrete in the mold.

Web formwork includes the forms on or within which the concrete is poured and the frames and bracing which provide stability. Web concrete forms and accessories. Carroll specializes in concrete form rental. The output results in great optimization of. Delivering form solutions for all construction needs. Web formwork (shuttering) in concrete construction is used as a mold for a structure in which fresh concrete is poured only to harden subsequently. Web formwork is a temporary structure that is used to support wet concrete until it hard. Web efco provides a wide range of formwork products to meet contractor needs in all concrete construction applications. Formwork solves this problem by creating a sturdy base to. Wall, slab, climbing, shoring, safety and components.

Formwork Safe Practices Checklist

In specialty applications formwork may be permanently incorporated into the final structure, adding insulation or helping reinforce the finished structure. When the idea of a form is this versatile, it is crucial that your conception of a construction form is flexible, requiring minimal change when needed. Formwork cost is 25 to 30% of the total cost. Safety inspections building inspections.

What Is Formwork In Construction 7 Types Of Formwork Used

Types of concrete formwork construction depends on formwork material and type of structural element. The inspection form is a template with all of the fields that need to be filled out by an inspector. To effectively develop a jobsite plan involves communication between all parties, including the concrete contractor and the formwork supplier. The inside surface is coated with a.

Different types of formwork? 4 tips for choosing effective formwork

Carroll specializes in concrete form rental. There are many different types of formwork available in market. Formwork can be of timber, steel, plastic, or fiberglass. Web formwork is the mould which is used in construction for giving desire structural shape by pouring concrete in the mold. Our products are safe, simple to use, rugged, and durable.

The Best Formwork for Concrete Structures Mosaic Mercy

We also provide forming and shoring products including: In simple word, formwork is a mold to cast concrete member in different shapes and sizes. In specialty applications formwork may be permanently incorporated into the final structure, adding insulation or helping reinforce the finished structure. The form will collect the profile of the contractor and the owner of the project as.

Wall Formwork Systems UCF

Usually, the form is easy to fill out, so it should not take you long to get the relevant information ready. The formworks are classified into several types which as follows: Web efco provides a wide range of formwork products to meet contractor needs in all concrete construction applications. Web construction loan agreement form. Web #1 inspection forms construction companies.

Types of Formwork for Concrete Structures

Web as a leading supplier of concrete forming and shoring products, cmc construction services specializes in commercial, industrial, civil, power and infrastructure projects. When the idea of a form is this versatile, it is crucial that your conception of a construction form is flexible, requiring minimal change when needed. Major 6 types of formwork used in construction. Web 16+ construction.

Concrete Formwork & Types of Formwork Shuttering CivilDigital

Delivering form solutions for all construction needs. When the idea of a form is this versatile, it is crucial that your conception of a construction form is flexible, requiring minimal change when needed. Web #1 inspection forms construction companies are required to perform routine inspections for many different purposes. Materials 1×4 wood boards for building the formworks 2×4 wood stakes.

Types Of Formwork In ConstructionFormwork Sydney My Reader Books

Our products are safe, simple to use, rugged, and durable. The form will collect the profile of the contractor and the owner of the project as well as the project’s subcontractors and their licenses. Usually, the form is easy to fill out, so it should not take you long to get the relevant information ready. In specialty applications formwork may.

Formwork Products Largest suppliers of high quality plywood products

Web concrete forms and accessories. Web precise aluminum forms are perfect for concrete multistory housing complexes such as apartments and condominiums. We have many options for forming concrete. Web efco provides a wide range of formwork products to meet contractor needs in all concrete construction applications. Wall, slab, climbing, shoring, safety and components.

Construction accident and injury prevention with prefabricated

In specialty applications formwork may be permanently incorporated into the final structure, adding insulation or helping reinforce the finished structure. Web precise aluminum forms are perfect for concrete multistory housing complexes such as apartments and condominiums. Web formwork construction is a process that helps construct buildings. Materials 1×4 wood boards for building the formworks 2×4 wood stakes to lock into.

Safety Inspections Building Inspections Machinery Or Equipment Inspections Vehicle Inspections

Web 16+ construction form templates. Web construction loan agreement form. We have many options for forming concrete. Types of concrete formwork construction depends on formwork material and type of structural element.

Usually, The Form Is Easy To Fill Out, So It Should Not Take You Long To Get The Relevant Information Ready.

In specialty applications formwork may be permanently incorporated into the final structure, adding insulation or helping reinforce the finished structure. The formworks are classified into several types which as follows: Formwork solves this problem by creating a sturdy base to. Web we’ve compiled the most useful free construction work order templates and forms for construction companies, architects, project managers (pms), general contractors (gcs), subcontractors, and inspectors.

To Effectively Develop A Jobsite Plan Involves Communication Between All Parties, Including The Concrete Contractor And The Formwork Supplier.

Web formwork includes the forms on or within which the concrete is poured and the frames and bracing which provide stability. Web a leader in concrete formwork and shoring systems. In simple word, formwork is a mold to cast concrete member in different shapes and sizes. A blank construction form is ideal for proving general information about a construction project.

The Inspection Form Is A Template With All Of The Fields That Need To Be Filled Out By An Inspector.

Formwork cost is 25 to 30% of the total cost. Materials 1×4 wood boards for building the formworks 2×4 wood stakes to lock into position the formwork for concrete 2×4 lumber for securing the forms nails/wood screws to fasten the formwork polystyrene sheets to insulate the foundation (optional) tools safety gloves, glasses The entire floor can be poured at one time using the modular system. We will have the right forms to fit your design and a knowledgeable staff to assist with your project.